Paving The Way Fundamentals Explained

Wiki Article

Our Paving Bricks Ideas

Table of ContentsThe 20-Second Trick For Paving The Way8 Easy Facts About Paving Stones Shown3 Simple Techniques For Paving MeaningThe 3-Minute Rule for Paving Stones

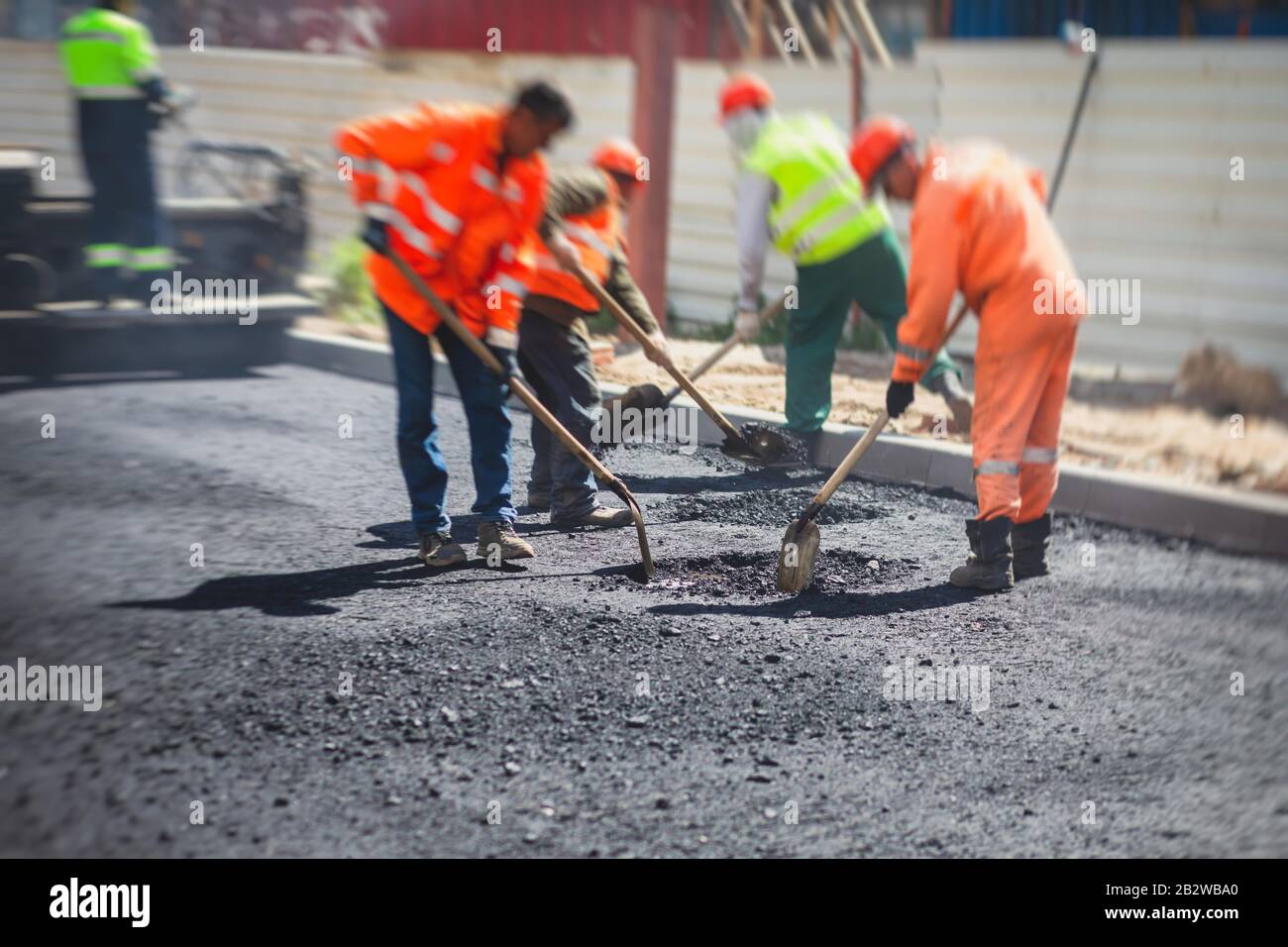

Asphalt concrete, additionally referred to as black cementing agent has been utilized for road construction for centuries. Asphalt is a combination of aggregates, binder, and filler, used for creating and maintaining roadways. Accumulations made use of in asphalt combination can be gravel, sand, crushed rock, or slags. In present times, to enhance the sustainability of the asphalt, specific waste and spin-offs are made use of, such as products arising from the change, building and construction, devastation, rehabilitation, or repair work of any type of manmade physical framework consists of residences, buildings, commercial or business facilities, as well as roadways.

Asphalt paving is a combination of 2 key active ingredients:1) Aggregates2) Asphalt binder, The aggregates have around 95% of the complete mix by weight. Aggregates are combined with 5% of asphalt binder to create asphalt pavement. The aggregates and also asphalt are heated to a proper temperature and also mixed in a processing plant qualified of creating specified materials.

The material is after that compressed to the called for level by heavy, self-propelled rollers, generating a smooth sidewalk course. Depending upon the elements such as ambient problems, to accomplish ample thickness, treatment is been taken that mix temperature level does not fall listed below optimal compaction temperature level while the material is compressed. 1) Warm mix asphalt 2) Warm mix asphalt 3) Half-warm mix asphalt 4) chilly mix asphalt, Hot mix asphalt (HMA) has a laying temperature level above 150C, it is one of the conventional paving methods utilized.

A Biased View of Paving The Way Meaning

e., 50% and 10to30%. It contains the 5 layers mentioned listed below (From bottom to top)1) Sub-Grade (150-300mm)The subgrade is a layer of natural dirt prepared to obtain the layers of the pavement and also is a base of all the payment layers. All the tension of the above pavement layers is transferred to Sub-grade.

The subgrade must be strong sufficient to occupy the stress and anxieties Enforced because of loads without shear failing or too much deformation. 2) Sub-base (100-300mm)It is the layer of the material between the Sub-Grade program and Base-Course. The sub-base is likewise understood as soling. The primary functions of the sub-base are to provide structural assistance, improve drain, as well as decrease the breach of penalties from the sub-grade in the sidewalk framework.

When it comes to the base training course, the training course is open-graded or has a huge air gap, the sub-base training course with more fine material can be used as filler between sub-grade and the base program. The course typically includes damaged stones, blocks, or aggregates. As the stresses in a sub-base are a lot reduced than those in the base, the material utilized is substandard to those in the base course.

5 Simple Techniques For Paving

Monday, November 23rd, 2015 The decision to have an asphalt driveway installed at your residence is an economic investment. This economic investment must provide the highest high quality of work as well as materials from the ideal Youngtown asphalt professional. There is a process of laying down asphalt and a qualified asphalt professional must follow this procedure so the house owner gets the proper asphalt required for their driveway.The foundation might require to have stones contributed to the ground so it can give a sturdy foundation. If the structure has a soft basing product or stumps and origins, then this all need to be eliminated initially, then stones can be contributed to the area. The structure is just one of the most vital functions of the asphalt.

The hot asphalt is laid on top of the sub-base, and also then rolled uniformly. The surface has a paver and also roller discuss the asphalt so the asphalt is distributed equally as well as compacted at the same time. The edges are hand tamped at a 45 level angle so it gives the support required for the asphalt.

The 30-Second Trick For Paving

You will be able to stroll on the asphalt 24 hrs after the asphalt is finished. You can park as well as drive on the asphalt 3 days later. The procedure for asphalt is not quick, however the wait is worth it in the lengthy run.Milling is the process of grinding off the leading layer of asphalt or surface area of a street. This is typically carried out in preparation for paving, although there are exemptions where no milling or just partial milling is required. paving the way. Resurfacing is the procedure of positioning click reference an asphalt overlay on a street, whether or not it has actually been milled.

Much of the work is done during the night in order to lessen interruptions to traffic - paving bricks. DOT takes actions to minimize the trouble, milling needs vehicles, special equipment and mobile lights. To minimize disturbance, machinery is fitted with sound reduction devices as well as teams attempt to keep noise to a minimum.

You may need concrete replacement or asphalt replacement. Regardless of just how well-laid the surfaces are, they will eventually wear out. You also may require brand-new asphalt or concrete on a substratum that formerly did not have a prepared paving a driveway cost surface. This short article will provide you with an easy to recognize review of these procedures.

Report this wiki page